Use SolidWorks to Make a Template for Cutting a “Fishmouth” into a Round Tube

Monday, March 28, 2011 at 1:54PM

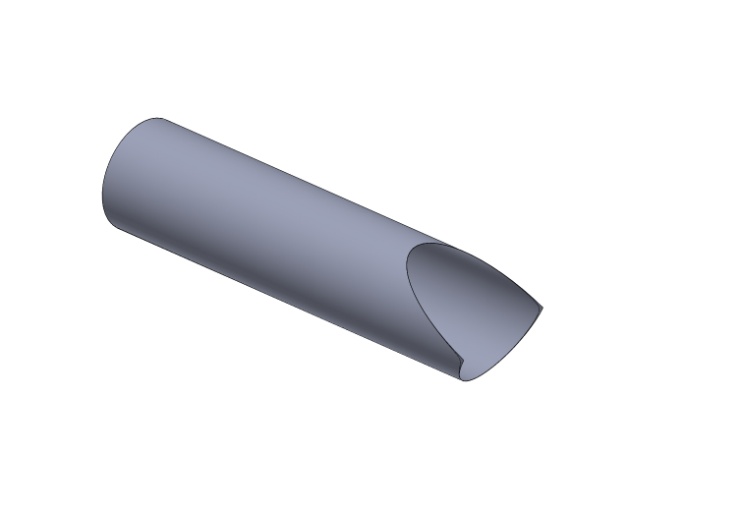

Monday, March 28, 2011 at 1:54PM SolidWorks can readily be used to create space frames consisting of round tubing or pipe members. The SolidWorks weldment commands will trim the tubular members where they intersect each other. When a round tube intersects another round tube the resulting end of the intersecting tube has a shape referred to as a “fishmouth”. See Figures 1 and 2. The fabrication of the “fishmouth” end of the tube can be problematic. In a production environment special machines can be used to create the “fishmouth” shape. One method is to use hole saws in a drill press while clamping the tube in a special vise. Another method uses a machine with a sanding belt passing over a roller with the same radius as the desired radius of the “fishmouth” cut. And most exotic of all are computer controlled laser cutters that rotate the tube and translate the laser head to create the “fishmouth” cut.

But what can you do to create the “fishmouth” cut if you only want to create a few cuts for prototype work without the expense of special equipment? SolidWorks can come to our aid by allowing us to make a template that is used to mark the end of a tube with the shape of the cut needed to make a “fishmouth”. The steps are as follows.

- Make the round tube frame in SolidWorks using the weldments commands. Trim the ends of the tubes with the Trim/Extend command. See Fig. 1

- Expand the Cut List. For each tube that requires a “fishmouth”, right click on the body in the Cut List and select “Insert into New Part”.

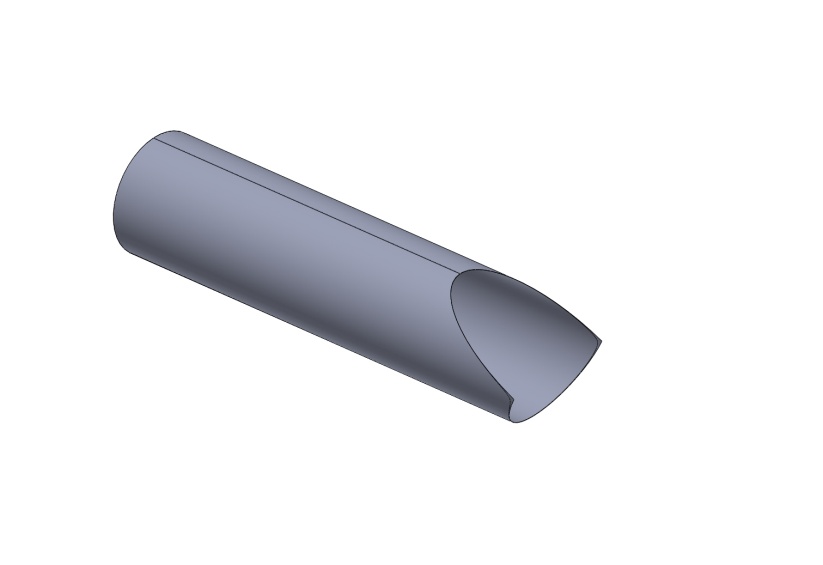

- Open the new part file. See Fig. 2

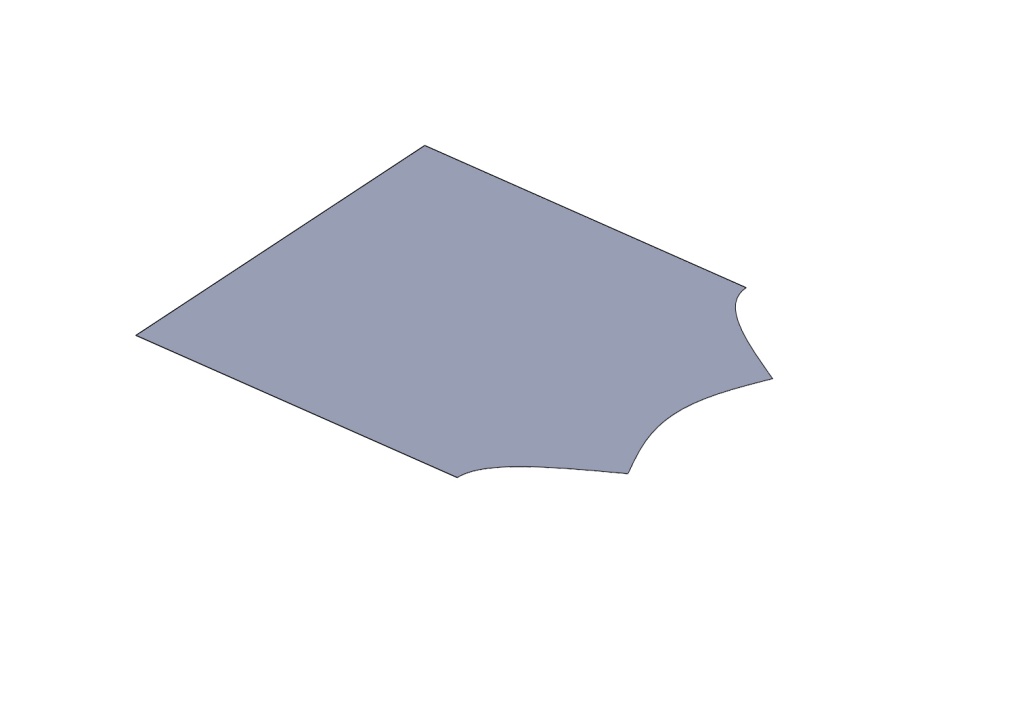

- Make a cut through the part model to create a very thin wall for the tube. See Fig. 3.

- Make a longitudinal cut through one wall of the part model. See Fig. 4.

- Use the Insert/Sheet Metal/Bends command and select one of the two outside longitudinal cut edges.

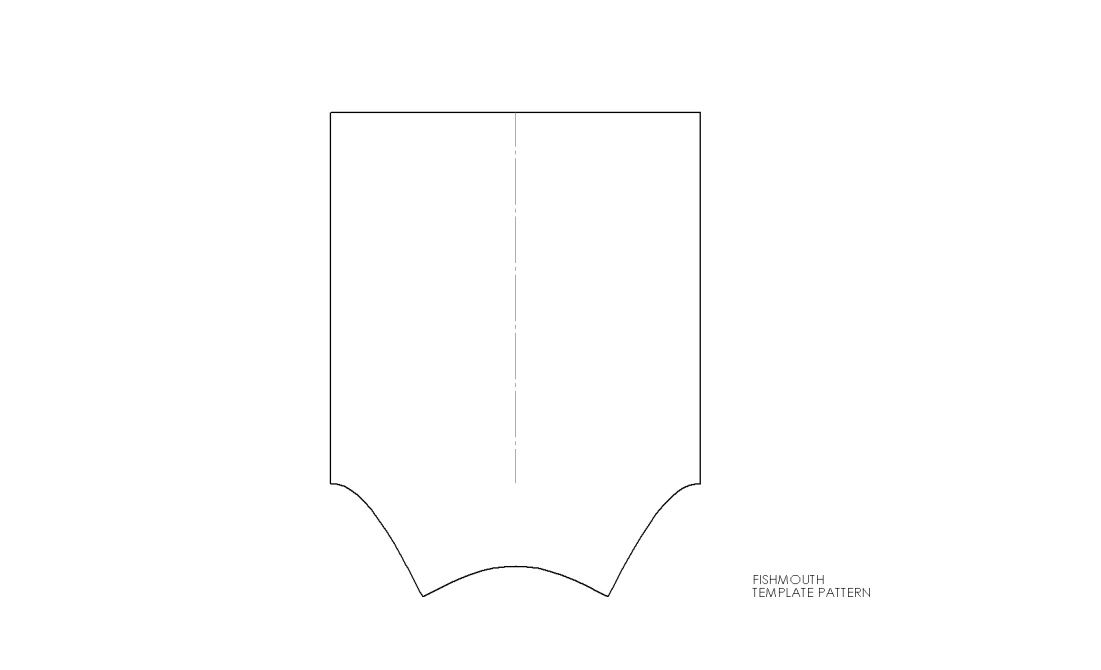

- Select the sheet metal “Flatten” command. See Fig. 5.

- Make a SolidWorks drawing at 1:1 scale of the flattened pattern. See Fig. 6.

- Print the drawing and cut out “fishmouth” flat pattern drawing.

- Wrap the pattern around the tube, orienting the pattern as required, and tape in place. Trace the edge of the pattern onto the tube with an indelible marking pen. See Fig. 7.

- Cut out the “fishmouth” shape with a cutting torch and dress the cut as required with a die grinder.

- Kendall

Figure 1

Figure 1

Figure 2

Figure 3

Figure 3

Figure 4

Figure 4 Figure 5

Figure 5 Figure6

Figure6

Figure 7

Figure 7

Phil | Comments Off |

Phil | Comments Off |